Why Modernize: The Limitations of Manual Factories

In today’s competitive landscape, traditional factories that rely heavily on manual labor and legacy systems are increasingly falling behind. Manual processes often result in lower efficiency, delayed responses to defects, and minimal data insights. According to McKinsey, companies that embrace Industry 4.0 can reduce machine downtime by up to 50% and improve productivity by 20–30%.

Moreover, manual operations lack transparency and real-time visibility. In contrast, smart factories enable end-to-end visibility, automation, and data-driven decisions. A smart factory integrates IoT, AI, cloud, and real-time analytics to enhance operational agility and reduce unplanned downtime.

What is a Smart Factory?

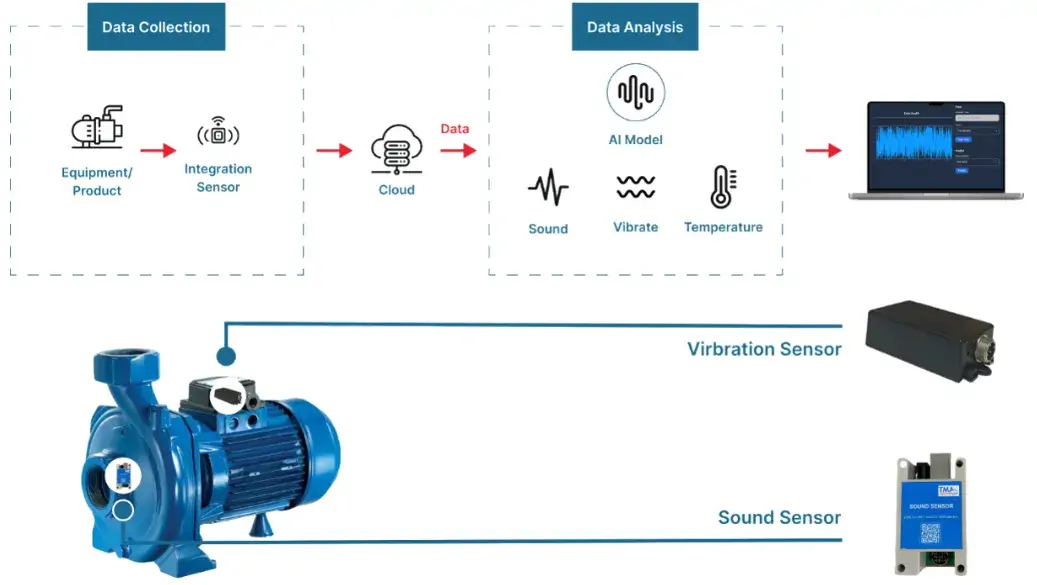

A smart factory is a highly digitized and connected production environment that uses smart machines and sensors to continuously collect and share data. This data is then used to make intelligent decisions in real time. IEEE defines smart manufacturing as the combination of cyber-physical systems (CPS), cloud computing, and cognitive computing to optimize production processes.

Key characteristics of a smart factory include:

Autonomous decision-making

Real-time performance monitoring

Predictive maintenance using AI and IoT

Scalable and reconfigurable production systems

From Manual to Smart: Key Differences

Transitioning from manual to smart involves both technological and cultural shifts. Factories must move from isolated systems to a fully integrated digital ecosystem.

A Roadmap for Modernization

According to MDPI, successful smart factory transformation follows a 5-level maturity model: from awareness, readiness, initiation, consolidation, to integration. Here is a practical roadmap based on industry experience:

Step 1: Assess Digital Readiness

Evaluate current infrastructure and data maturity.

Identify legacy systems and integration points.

Step 2: Start with Pilot Projects

Choose a high-impact area such as predictive maintenance or energy monitoring.

Use low-risk pilots to build confidence and gather insights.

Step 3: Connect Machines and Collect Data

Deploy IoT devices to monitor temperature, pressure, energy usage.

Ensure connectivity with protocols like MQTT, OPC-UA.

Step 4: Apply AI and Analytics

Use machine learning for fault detection and production optimization.

Apply predictive maintenance to reduce unexpected failures.

For example, AI models can predict equipment failure 3–5 days in advance, allowing for proactive intervention.

Step 5: Expand and Integrate

Connect systems like MES, ERP, and PLM.

Develop centralized dashboards for real-time decision-making.

Step 6: Change Management and Workforce Enablement

Train staff in new tools and processes.

Create cross-functional teams to lead the transformation.

Challenges and Success Factors

A study from Springer highlights key challenges such as data silos, lack of skilled workforce, and change resistance, which are common in traditional factories. Success depends on strong leadership, a clear vision, and continuous improvement cycles.

Firms that embraced a phased rollout, focused on scalable architectures, and embedded cybersecurity by design were more likely to succeed.

How TMA Solutions Supports Smart Factory Modernization

Predictive Maintenance: A leading Vietnamese manufacturer of plastic valves partnered with TMA to tackle recurring quality issues on their production line. Although the factory had adopted partial automation, defective products still slipped through, causing material waste and threatening brand reliability. To solve this, TMA implemented an AI-powered sound detection system that continuously analyzed audio signals during production. The system detected subtle acoustic anomalies to identify faulty items in real time, triggering visual alerts for operators and logging data for reporting and predictive maintenance. The results were significant: product pass rates increased to 99%, manual inspection was largely eliminated, and the factory scaled production without additional labor costs. This successful collaboration highlighted how AI and sound analytics can transform traditional manufacturing challenges into smart, scalable solutions, laying the foundation for more intelligent, autonomous factory operations.

Conclusion

Modernizing from a manual to a smart factory is no longer optional; it's a strategic necessity. As global manufacturing becomes increasingly data-driven and agile, factories that continue to rely on traditional methods risk falling behind. The journey may seem complex, but with a clear roadmap, trusted technologies, and the right partner, the transformation can be both practical and rewarding. More than just automation, smart factories represent a shift toward intelligent operations powered by real-time data and human–machine collaboration.

Table Of Content

Start your project today!